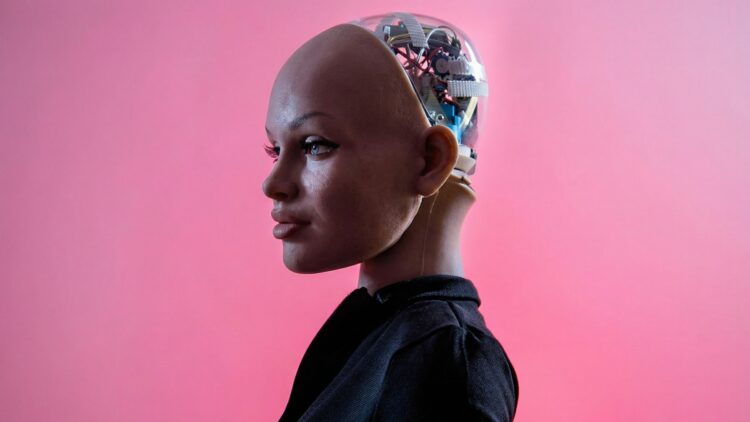

Many of the “humanoid” robots you see these days don’t actually look human, like the one that recently played one-on-one with Dallas Mavericks star Kyrie Irving. In contrast, the sophisticated robots made by Toronto’s Realbotix look incredibly like real people and use special vision systems to interact with staff and the public.

Realbotix announced that one of its robots will handle employee training, connect with stakeholders, and guide interactive tours at Ericsson’s Imagine Studio in Plano, located north of Dallas.

Realbotix says it is leading the way in “human-centric robotics” by using patented tech that allows for realistic facial expressions, sight, and social skills. The company stated that the robot heading to Plano will work as “a dynamic, adaptable human–robot interface” for practical, real-world tasks.

In one specific role, the robot will give local Ericsson staff members tailored development plans, making it easier to grow their careers using a data-focused approach.

Ericsson also plans to use the robot to reach out to schools and offer career advice, motivating students by providing “personalized career guidance” and pointing out “pathways for success” in the tech world.

Humanoid robots becoming essential teammates on the job

Andrew Kiguel, the CEO of Realbotix, remarked that Ericsson’s use of the robot in Plano proves there is growing trust in AI-powered humanoids, connecting advanced tech with real-life needs.

“This step is a huge jump for Realbotix, setting up our humanoids as vital coworkers that will define what the future workplace looks like,” Kiguel added.

Other industries are also making use of artificial intelligence

Talk about using robots in factories and shipping hubs heated up earlier this month at the Consumer Electronics Show in Las Vegas, after Hyundai and its partner Boston Dynamics announced a huge new plan for AI-driven robotics.

Their presentation featured Atlas, a human-shaped robot running on artificial intelligence that is designed to take care of dull, repetitive tasks in warehouses and plants. Boston Dynamics already has Spot, its four-legged robot, busy at power stations worldwide, including on BP platforms in the Gulf of Mexico where it reads meters, scans for corrosion, and hunts for methane leaks.

Hyundai stated that they aim to expand their robot technology into sectors such as shipping, energy, construction, and facility maintenance. Other firms also presented robots designed specifically for work in the energy industry.

DEEP Robotics, a manufacturer based in China, showcased their Jueying X30 model, which has become a leader in energy site inspections because its self-driving system can locate itself indoors with centimeter-level accuracy.

The group recently deployed a robot named “SPock” to patrol areas of a 40-kilometer underground power tunnel in Singapore, making it the first time a Chinese quadruped robot has been utilized in a foreign power grid.

Automated day labourers at logistic centers

Meanwhile, hundreds of miles away in an Ohio warehouse, the metal walls of a 53-foot trailer radiate heat like a toaster in the middle of summer. For years, a worker wearing steel-toed boots would have to walk in, drag 70-pound boxes onto a roller, and just pray their back didn’t give out.

Those days are gone. Now, a yellow robot called Stretch moves up the ramp, lifts its vacuum-powered arm, and tears through the stack of packages at a rate of roughly 580 boxes an hour, which is almost double the speed of the quickest human team.

DHL, the massive delivery company running this site, was so impressed with the performance that they ordered over a thousand units from Boston Dynamics. UPS, FedEx, Walmart, and many third-party logistics firms are trying out similar equipment, banking on the idea that AI has finally solved the toughest, sweatiest—and most dangerous—task remaining in modern shipping.