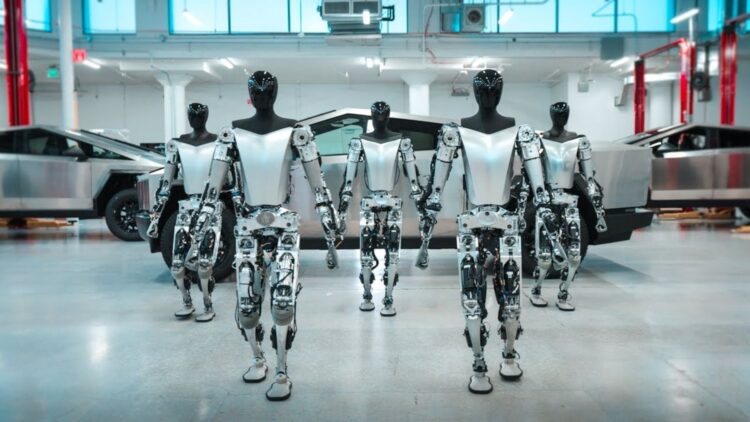

Have you ever heard about Elon Musk? I’m sure you have. He is the protagonist of today’s article because his company Tesla has started mass producing a humanoid robot called Optimus Gen 3, which could work for hours and hours with no rest. This innovation affects the way in which products are manufactured, and makes us wonder about the environment, employment, and the future of the industry. So, let’s see what this humanoid robot is all about.

The Optimus Gen 3

This is a robot designed to help in fabrics and repetitive tasks. Now, let’s learn about its main features:

- Around 1.70 meters tall and 57 kilograms, similar to an adult human.

- Runs on a battery that allows 10 to 12 hours of continuous work, roughly a full shift.

- Hands with 22 different movements, able to handle small parts and heavier items with human-like precision.

- Uses a version of Tesla’s self-driving computer as its “brain,” learning tasks by observing humans rather than following fixed scripts.

- Capable of performing over 3,000 tasks, from moving parts to inspecting products and cleaning.

Elon Musk aims to produce up to a million of these robots per year in his Fremont fabric (California), although he warns the production will be slow at the beginning.

Elon Musk hopes these robots help the environment

One of the most interesting points about this project is its possible impact in the environment, since they can help reduce emissions if:

- They execute tasks in a more precise and efficient way, reducing waste.

- They accelerate the production of clean technologies like electric vehicles, batteries, and solar panels.

However, each robot consumes a lot of electricity, and if millions of robots are used with non renewable energy, they could increase this consumption and emissions. About this, Musk’s company stated that its fabrics operate with 100% renewable energy which could make these robots the allies for a cleaner future.

Workers and the industry

Elon Musk’s project also changes the role of human workers. The idea is that robots take over dangerous tasks, repetitive jobs, and boring, manual work. This could reduce workplace injuries and allow people to focus on more skilled roles.

At the same time, labor unions warn about job losses and call for agreements before deploying robots on a large scale. Hyundai’s experience with Atlas robots in South Korea shows workers need protections to avoid negative impacts.

Competition

Is Tesla the only company interested in producing humanoid robots? Of course not. Let’s see what other companies are competing against Tesla:

- Hyundai plans mass production of Atlas robots by 2028.

- Chinese companies and startups like Figure AI are developing robots for factories and warehouses.

- Advanced AI models, such as Google DeepMind, are being paired with these robots to expand their capabilities.

However, Elon Musk aims to stay ahead with Optimus Gen 3’s large-scale production, which could transform how factories operate worldwide.

So…

With the passage of time, we are surrounded by more and more technology and we should have in mind that the choices made today (how we use energy, protect workers, and integrate AI responsibly) will shape whether this new wave of technology becomes a tool for a cleaner, safer, and more efficient future, or simply another source of hidden problems.

But, are we ready to embrace a future where machines share our workplaces, or do we need to pause and plan carefully first?